Printed circuit board 4.0

July 27, 2018

Blog

Automation is increasing rapidly. The generation currently coming up has already been dubbed ?Native Robotics.?

Automation is increasing rapidly. The generation currently coming up has already been dubbed “Native Robotics.” Circuit boards are at the heart of all electrical appliances, automobiles, robots, smartphones, tablets, and more. A printed circuit board must therefore be reliable and meet increasing quality demands – yet manufacturing costs must decrease even as the complexity of the end product increases.

An order via a control board is placed with one of the MES service providers in Germany. After being entered, the order is scheduled, production commences, and all relevant production and quality data are stored in the backend system (a database). The complete process is controlled centrally from the leading backend system. Although the printed circuit board is clearly detected during production, possibly via a lasered 2DCode, the printed circuit board is unaware of any process parameters or quality features.

Although this is a very simplified explanation, this is the classic process of how a printed circuit board is created. But this is not the future, as it is far too expensive and inflexible in terms of the lifecycle. There is a lot more Industry 4.0 in a printed circuit board than many people imagine.

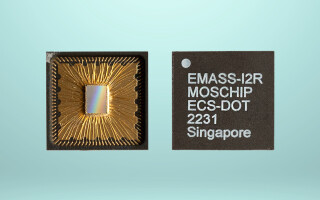

The raw circuit board is loaded with memory at the time of its manufacture. In addition, it can actively influence all other processes – not just in production, but over a lifetime. A small UHF RFID chip with a tiny antenna structure makes this possible. This is wholly unnoticeable embedded in the circuit board. The space requirement is comparable to a 2DCode.

From now on, even the raw circuit board can store production data that is retrievable at any time, e.g. the date of manufacture and properties such as thickness and number of layers. Of course, it can be uniquely identified as well, even in bulk and over relatively large distances. Ranges greater than one meter are not unrealistic. Warehousing logistics processes can therefore already be optimised by automated (bulk) detection.

When the circuit board reaches the MES service provider, the placer, and finally the SMD production line, the circuit board or panel on the production line logs in. Manufacturing machines with integrated UHF RFID technology make this possible. Circuit boards can be recognized, the stored information can be read as well as updated or supplemented if necessary. Parameters such as when, on which machine, and with which production time are only some of the variables which can be stored. Even special events such as relevant disturbances within a production machine can be stored. If the printed circuit board or the panel is manually fed to a new manufacturing process after being unstacked, the circuit board can indicate if it should be there – or whether it potentially needs to go through another process step.

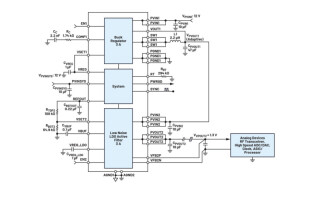

All this is made possible by state-of-the-art UHF RFID technology. Thanks to the coaxial cable-based Ha-VIS LOCFIELD antenna and the flexible UHF RFID reader Ha-VIS RF-R350 from HARTING, implementation is possible with little effort. The LOCFIELD is a space-saving antenna that enables data communication with the circuit boards within the production line. The antenna array follows a coaxial conductor and therefore allows communication at full speed with multiple boards in a board panel. Thanks to flexible and standards-compliant data processing by the UHF RFID reader-writer Ha-VIS RF-R350, data can be preprocessed directly in the reader.

Reader and antenna can be easily integrated into new and old systems. The compact design and the high (IP67) degree of protection also make retrofitting easier. Full data integration into production systems is possible at any time but not mandatory. Of course, existing backend systems can and should be integrated, too. The solution can grow very easily and flexibly in tandem with the demands and ideas of the PCB placer and its customers.

The data storage on the RFID chip of the printed circuit board conforms to ISO standards and GS1 standards, which are already familiar from commercial freight transport. Not only the ID of the circuit board itself is meant here, but also the process and manufacturing data, which are stored in the RFID chip’s so-called user memory. Everything is transparent and can be easily used later by third parties as well.

Embedding the UHF RFID chip directly into the raw circuit board is certainly the most elegant solution, but not the only one. The embedded chip, which thanks to a Beta LAYOUT process is used fully automatically in the printed circuit board, allows the entire lifecycle and the entire production chain to be mapped directly in the printed circuit board. Even during the placement process, the chip can be applied to the circuit boards as an SMD component. muRata offers corresponding UHF RFID chips and transponders via its MagicStrap.

Once equipped with UHF RFID technology, this can, of course, be used on demand for an entire circuit board lifetime. In addition to warehouse logistics applications – since bulk detection of multiple boards at once is possible – e.g. repair processes can be optimised. Even if the printed circuit board no longer works, i.e. can no longer be switched on, stored information such as delivered firmware versions can still be queried.

In addition, the information can also easily be queried if the board was already installed in a finished product. As long as the housing is not completely made of metal and certain basic physical principles are adhered to, the information contained in the RFID chip can continue to be used and updated. The possibilities of the UHF RFID technology are available until the PCB is disposed of and can facilitate and improve various applications.

Is this all mere theory, or is it already being implemented? Nokia is already taking advantage of UHF RFID-based PCB manufacturing in its new modular Industry 4.0 production line. The first products produced there are already equipped with UHF RFID transponders. The machines used by various manufacturers, including a reflow soldering system from Rehm Thermal Systems, are equipped with the described UHF RFID products from HARTING and thus meet the requirements of Industry 4.0-capable printed circuit board production.

ASM Assembly Systems GmbH & Co. KG also integrates RFID technology into its machines. Machines and printed circuit boards are not the only things that can be equipped with RFID technology. Consumables such as cleaning rollers used in solder paste printers can also be detected automatically. Associated products are offered by the company Vliesstoff Kasper. Zollner Elektronik AG has been demonstrating the possibilities of this technology for some time now in its technical centre in Cham.

The consortium’s comrades-in-arms have numerous ideas to use the UHF RFID technology in even more versatile manner. Among other things, the TU Dresden is involved in efforts to develop completely new modules.

UHF RFID technology makes the circuit board industry even more versatile, manufacturing processes more flexible and safer, and opens up completely new application scenarios, up to and including improving the sustainable handling of the raw materials of a printed circuit board and through to proper disposal. HARTING is already working on other ideas and will work together with its partners to implement them.