Workload Consolidation for the Rugged Edge in Industrial Designs

February 24, 2020

Story

Workload consolidation is making a foray in embedded systems serving the rugged edge in industrial automation, fleet management, smart cities, and more.

Workload consolidation is making a foray in embedded systems serving the rugged edge in industrial automation, fleet management, smart cities, and more. In other words, embedded systems are starting to move away from the traditional architectures in which different subsystems are dedicated to specific applications, to more scalable options in which compute and connectivity resources are converging on a single piece of hardware or computing platform.

However, before we delve into how workload consolidation is shaping the rugged edge designs, let’s begin with what is rugged edge and what are the hardware requirements that define the rugged edge. Moreover, why it’s not so easy to deploy Internet of Things (IoT) devices in rugged environments.

As edge computing expands from controlled environments in offices and datacenters to more challenging conditions in manufacturing and automation, the edge computing needs to be ruggedized not only from mechanical and thermal engineering standpoints, but also in their ability to offer features and characteristics at the system level in a more flexible manner.

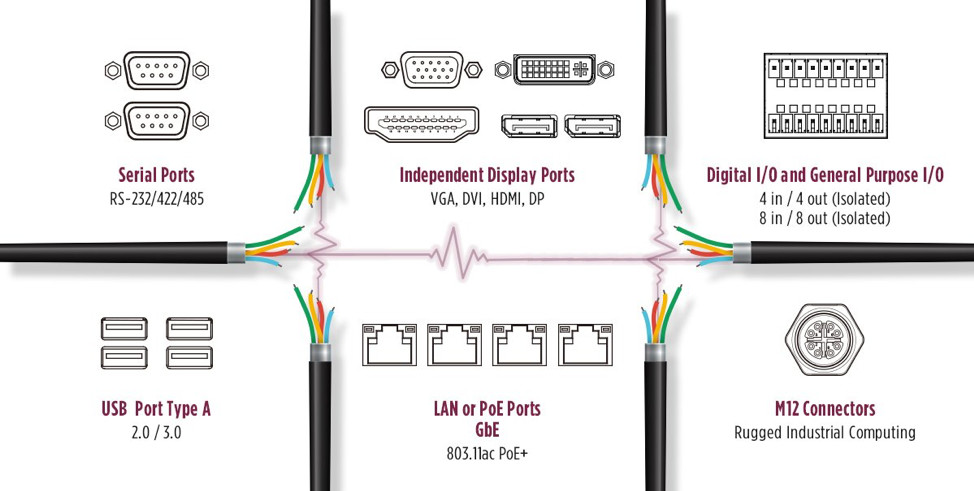

Figure 1: The rugged edge designs demand a lot of I/Os, spanning from ports for industrial applications to ports for security surveillance that leverage the Power-over-Ethernet (PoE) links. Image: Premio

Case in point is mobile applications like intelligent transport for fleet management where vehicles are constantly in motion and require robust connectivity for passing telemetry data back and forth through wireless links.

Then there are self-service kiosks deployed in remote and rugged locations. Here, besides resistance to shock, vibration and extreme temperatures, what’s also crucial in the design of outdoor kiosks and vehicle monitoring systems is workload consolidation in the form of a right combination of compute, storage, connectivity and I/O variety to ensure efficient and reliable remote manageability at the edge.

Workload Consolidation at IoT Edge

The edge computing now comes equipped with multi-core processors, enormous data storage, and a variety of I/O options. Next, there are scalable compute options in the form of hardware accelerators that lower the CPU power and leverage machine learning capabilities that previously designers only got from GPUs for inference analysis.

So, it’s imperative that edge nodes, tasked with analyzing data and acting in real-time, can optimize these resources for a wide range of workloads. This new demand makes workload consolidation a key foundation for mobility and remote deployments that heavily rely on mission-critical capabilities to ensure 24/7 reliability due to the lack of on-site technical support in remote applications.

Take, RCO-3400 rugged edge embedded computer, for instance, which offers improved processor speeds for heavier workloads powered by the 7th Gen Intel Core Mobile-U processors (Figure 2). The low-power BGA processors (Mobile-U) facilitate a robust fanless design in this rugged edge embedded computer. RCO-3400 is a powerful as well as a compact machine that is tested to withstand damaging environmental elements like wide temperature (-40C to 70C), wide voltage and power protection (9VDC – 50VDC), and shock and vibration (5gRMS vibrations and 50G Shock).

That, along with support for PCIe Gen 3 interface for high-speed interconnects and DDR4 memory for volatile cache, allows embedded system engineers to carry out data logging and monitoring, surveillance, and other IoT edge applications in mobile and remote environments.

Figure 2: The edge computer employs multiple connectivity options to serve transportation applications like remote fleet management. Image: Premio

Another industrial edge computer, VCO-3400, facilitates machine vision applications in factories and other industrial environments. Apart from ample compute power and storage capacity, the fanless vision computer offers up to 4x PCI expansion slots in addition to isolated DIO and COM port support for legacy device integration. The VCO-3400 is specifically designed for machine vision applications with the most critical I/O ports positioned in the front for DIN-rail support.

The design examples above also underscore the fact that besides multi-core processors and high-density memory, the flexibility of modular I/O and expansion slots are significant in balancing and offloading a wide range of complex IoT workloads. This allows edge computers with optimal port access to optimize functionality for different scenarios with a variety of interfaces and control capabilities.

Hardware security and encryption of critical data is one of the most important challenges as machines communicate bidirectionally . The IoT security is especially critical in rugged edge designs serving mobile and remote applications. Here, rugged edge computers like RCO-3400 and VCO-3400 offer the option of implementing the Trusted Platform Module (TPM 2.0), the latest hardware specification that safeguards computing devices with cryptographic keys.

TPM 2.0 prevents authentication keys from being exported while recording and autonomously reporting software uploads during the boot process to thwart malware attacks.

A Key Trend in 2020 and Beyond

Workload consolidation is driving changes for industrial embedded computers and edge computers, and this is going to be a key design trend in 2020 and beyond. Balancing workloads near the source of data, for example, will help rugged edge designs to cater to newfound opportunities in real-time AI inference.

The convergence of operational technology (OT) and information technology (IT) domains is another area where workload consolidation is going to condense the compute resources to save costs and raise efficiency for industrial IoT (IIoT). Especially, in the digital manufacturing processes increasingly adopted in food processing plants and automotive factories, this alignment between OT and IT worlds will be crucial in eliminating the technology solos and disparate architectures.