Standardization Key to Next-Generation In-Vehicle Sensor and Display Connectivity

July 16, 2021

Story

Image sensors and displays are at the forefront of automotive development, enabling breakthroughs in safety, automation, and user experience. To capture the full potential of these technologies, manufacturers need standardized sensor and display interfaces that streamline integration and meet the feature and performance demands of future applications.

Advanced driver-assistance systems (ADAS), digital cockpits, in-vehicle infotainment services, and autonomous driving systems (ADS) are creating a need for more cameras, sensors, and displays. Emerging features such as rear backup cameras, lane-keeping and sign-detection sensors, and 360-degree camera, lidar, and radar systems are heightening demand for high-bandwidth, low-latency, asymmetric network connections. Functional safety, security, and reliability are essential for these links.

The proliferation of new image sensors around vehicles and increasing number of in-vehicle displays is driving the need for high-performance data links that meet functional safety and security requirements.

Automakers need to integrate these components and interfaces under increasingly strict limits on space, weight, cost, and energy consumption. Fragmented technology poses a major challenge to this task. To date, the auto industry has had to rely on proprietary physical-layer interfaces, which has made integration and adherence to quality and regulatory standards more expensive, complex, and time-consuming - limiting the automakers' choice of technologies and suppliers.

A standards-based approach to camera, sensor, and display connectivity is essential for future automotive architectures. In this segment we explore how standardization offers the automotive industry the same benefits it has brought to many other technology sectors: interoperability, streamlined integration, faster time to market, lower costs, a larger ecosystem of suppliers, and accelerated innovation.

Physical Layer Foundation

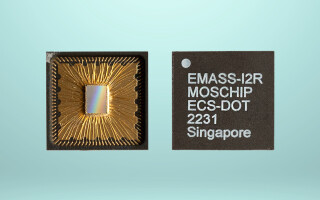

The MIPI Alliance developed MIPI A-PHY, the first industry-standard, asymmetric long-reach serializer/deserializer (SerDes) physical layer interface, as the first step to standardizing image sensor and display connectivity. A-PHY forms the foundation of MIPI Automotive SerDes Solutions (MASS), an end-to-end framework for connecting cameras, sensors, and displays within vehicles over MIPI Camera Serial Interface (MIPI CSI-2), MIPI Display Serial Interface (MIPI DSI-2), and other protocols. Together, A-PHY and MASS provide a framework that also builds in functional safety, security, and data protection.

A-PHY is designed to provide high-performance links between automotive image sensors and displays, and their associated electronic control units (ECUs) anywhere in a vehicle. It provides an asymmetric data link in a point-to-point or daisy-chain topology with high-speed unidirectional data, embedded bidirectional control data, and optional power delivery over a single coax or shielded differential pair (SDP) cable. Because A-PHY is built for high-speed asymmetric data transfers, it complements symmetric backbone technologies such as automotive Ethernet. A-PHY is optimized for linking resource-constrained edge components to computing nodes, providing high bandwidth in one direction while allowing the edge components to be smaller and less complex.

MIPI A-PHY v1.0 supports downlink data rates of up to 16 Gigabits per second (Gbps) with a 100 Megabits per second (Mbps) uplink.

A-PHY v1.0, introduced last year, includes the following features:

- High reliability—Ultra-low packet error rate of 10-19, or less than one error in the lifetime of the vehicle

- High resiliency—Ultra-high immunity to electromagnetic compatibility (EMC) effects in challenging automotive conditions

- Long reach—Up to 15 meters

- High performance—Downlink data rate of up to 16 Gigabits per second (Gbps) with a 100 Megabits per second (Mbps) uplink

- Low latency—Fixed latency as low as ~6µs, depending on speed gear

A-PHY v1.1, which is scheduled to be released by the MIPI Alliance later this year, will double the maximum downlink data rate from 16 to 32 Gbps by supporting dual downlinks over star quad (STQ) cables. It will also double the uplink speed from 100 to 200 Mbps. In addition, A-PHY v1.1 will expand PAM4 encoding to lower gears (G1 and G2), reducing the operating bandwidth of these gears and allowing OEMs, Tier1s, and suppliers to implement A-PHY using lower cost legacy cables and connectors.

Streamlined Development with Existing Interfaces

Using A-PHY, manufacturers can build end-to-end links throughout a vehicle using image sensor and display protocols—such as MIPI CSI-2 and DSI-2, and VESA Embedded DisplayPort/DisplayPort (VESA eDP/DP)—that are already widely used in automotive applications today.

MIPI A-PHY can be embedded directly in vehicle image sensors, displays, and ECUs, allowing for direct end-to-end data links with functional safety, security, and HDCP services implemented at every point.

A-PHY can be implemented in a phased approach. Initial implementations will likely use CSI-2 and DSI-2 over short-reach C-PHY or D-PHY interfaces with "bridges" to long-reach A-PHY. These initial implementations eliminate the need for proprietary bridges, reducing vendor lock-in and improving economies of scale. A-PHY implementations will then become more streamlined with the integration of A-PHY directly into sensors and displays, allowing for end-to-end A-PHY links to ECUs, as shown in the diagram above. Without bridges, manufacturers can further reduce cost, complexity, power consumption, and weight. In some cases, integration may happen first in one end of the A-PHY link or the other, such as integration into the graphics processor first before integration into the display module.

Full-Stack Implementation

As mentioned earlier, MIPI Automotive SerDes Solutions (MASS), built from A-PHY, creates a full automotive connectivity stack, incorporating higher-layer application protocols, A-PHY adaptation layers, the standardized MIPI Camera Command Set (MIPI CCS) and Display Command Set (MIPI DCS), and functional safety and security enablers.

The MASS protocol stack extends from the application to the physical layer.

As shown in the diagram, sitting above A-PHY are protocol adaptation layers (PALs) that map higher-layer protocols, including MIPI CSI-2, MIPI DSI-2 and VESA eDP/DP, to A-PHY's A-Packet format. In addition, PALs for interfaces used for command and control are also supported.

In the next layer, the MIPI Camera Service Extensions (CSE) and Display Service Extensions (DSE) specifications define services that enable functional safety and security, applied at the protocol level, to protect automotive data streams. Along with features of A-PHY, these services provide capabilities defined in the ISO 26262 automotive safety standard, giving engineers the tools they need to build systems meeting ASIL (Automotive Safety Integrity Level) requirements at any level, from ASIL B to ASIL D.

The key functional safety enablers available in MASS include the following:

- Frame counter—Detects a frozen frame on a display to prevent conditions such as a frozen video stream from a safety-critical camera

- Link detection failure—Detects a bus failure that interrupts the data stream

- Timeout monitor—Detects any temporary loss of data between a camera or display and an ECU

- Cyclic redundancy check—Detects accidental changes to data so corrective action can be taken against corruption

- Message counter—Provides replay protection by assigning a number to each packet, which can be used to detect an attacker's attempt to replay the same message

In addition, DSE enables support for optional high-bandwidth digital content protection (HDCP) services, which can be implemented over both DSI-2 and VESA eDP/DP display links. HDCP prevents unauthorized copying of display content, particularly for in-vehicle entertainment content.

Security enablers for confidentiality, integrity, and authentication will be added to MASS through future MIPI security specifications and updates to CSE and DSE, expected in the first half of 2022.

Use-Case Examples

A-PHY and MASS will ease integration of image sensors and displays and provide a standardized way to incorporate reliability, safety, and security in critical vehicle systems. Two example use cases illustrate how they make this possible.

Rear Backup Camera

In this example a rear-mounted camera aimed behind the vehicle delivers real-time video to a high-definition display, alerting the driver to objects in the car's path. The camera streams image data, using CSI-2 over A-PHY, directly to an ECU. After the ECU processes the data, it transmits a real-time video stream to a dashboard display, using either DSI-2 or VESA eDP/DP directly over A-PHY.

A-PHY and MASS allow for transfer of real-time image data from a rear backup camera to an ECU, where it is converted to a video stream to a dashboard display. Functional safety, security and content protection can be implemented at each stage.

Lane-Keeping Camera

In this example a front-facing, high-resolution CSI-2 camera captures real-time images of road markings. In some cases, the camera module may do some pre-processing to determine the car's position in the lane. It also transfers image data to an ECU using CSI-2 directly over A-PHY. The ECU can take in data from multiple sensors and perform sensor fusion for ADAS or automated decision-making.

A-PHY and MASS allow an ECU to take in data from multiple sensors and perform sensor fusion for ADAS or automated decision-making. Functional safety, security, and content protection can be implemented at each stage.

In both examples, functional safety and security functions are implemented at each point in the chain to ensure an ultra-low error rate and end-to-end protection against intentional or unintentional tampering. These closed-loop MASS implementations ensure the image sensors and displays work reliably, while A-PHY's low latency and high data rate enable high-quality image transfers under strict timing requirements.

Wide-Ranging Benefits

The introduction of A-PHY and MASS represents an opportunity for standardization of high-speed, asymmetric, in-vehicle data links that can benefit all partners in automotive development.

Vehicle designers will be able to leverage a complete framework for end-to-end connectivity with reliability, resiliency, functional safety, and security, significantly simplifying the integration process, and enabling OEMs and Tier 1 suppliers to amortize engineering costs over larger volumes of components. Interoperability will expand the ecosystem of suppliers, system integrators, and providers of services such as testing, which will improve economies of scale and lower bill-of-materials costs. Streamlined integration will help automakers bring new platforms and features to market faster to meet changing consumer demands. Most importantly, the use of standards will allow manufacturers to focus more on innovative new features rather than the development of lower-layer connectivity solutions that do not provide marketplace differentiation.

Like the computing and mobile-device sectors, the automotive industry can use these industry standards as a platform from which to offer continuing performance advancements in the products they develop.

(MIPI A-PHY has also been adopted by IEEE as IEEE 2977-2021.)

Rick Wietfeldt, Ph.D., is senior director of technology at Qualcomm Technologies Inc. He is a director on the MIPI Alliance Board of Directors, as well as chair of the IEEE MIPI A-PHY Adoption Working Group and co-chair of the MIPI Security Working Group.