Touch controller and display driver integration (TDDI) innovations

March 23, 2017

Touchscreen performance and efficiency is a make-or-break proposition for embedded devices employing them. And the advancements and options for touchscreens may surprise you. Synaptics has made...

Touchscreen performance and efficiency is a make-or-break proposition for embedded devices employing them. And the advancements and options for touchscreens may surprise you. Synaptics has made several announcements over the past few months related to advancements and customer applications for TDDI.

I caught up with Kevin Barber, Senior Vice President and General Manager of Synaptics to talk about the implications of TDDI in their Clearview R6A354 display driver solution for the automotive market. But before digging into the applications, a brief tutorial on on-cell, in-cell, and TDDI architecture is in order.

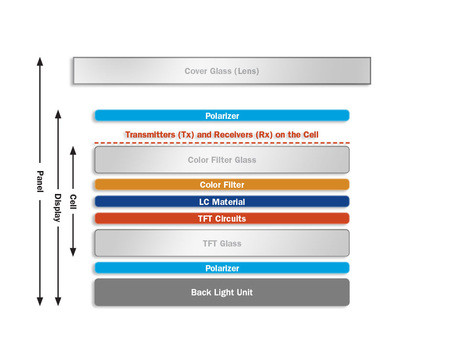

On-cell touchscreen architectures are the current mass-market solution. Using this approach, transmitters and receivers are built on top of a color filter glass layer. This approach is a good choice for active-matrix organic LED displays and larger/curved/flexible displays.

The in-cell architecture puts the transmitters and receivers in the cell layer itself. This optimizes cell efficiency while enhancing image quality. Full in-cell designs need just a single flexible printed circuit connector, which reduces cost and increases reliability.

The in-cell architecture puts the transmitters and receivers in the cell layer itself. This optimizes cell efficiency while enhancing image quality. Full in-cell designs need just a single flexible printed circuit connector, which reduces cost and increases reliability.

Synaptics TDDI integrates touch and display drivers, which improves design and manufacturability. There are a number of wins including better touch performance, lower cost, reduced power consumption, lower complexity, and greater reliability.

Synaptics TDDI integrates touch and display drivers, which improves design and manufacturability. There are a number of wins including better touch performance, lower cost, reduced power consumption, lower complexity, and greater reliability.

According to Barber, “TDDI simplifies the supply chain. Instead of a three-component procurement – touch screen, touch sensor, module housing – TDDI enables everything to be built into the display itself. Eliminating additional layers results in a thinner, bright display due to fewer layers being less reflective.”

According to Barber, “TDDI simplifies the supply chain. Instead of a three-component procurement – touch screen, touch sensor, module housing – TDDI enables everything to be built into the display itself. Eliminating additional layers results in a thinner, bright display due to fewer layers being less reflective.”

Barber also mentioned typical TDDI geometries are around 7” or less, but there is no technical challenge to accommodating larger geometries. “Touchscreens larger than seven inches are a much more fragmented market and it’s a volume/cost trade-off more than a technical issue”.

The Synaptics R6A354 display driver (DDIC) solution leverages these technology advances to provide broad, high-definition resolution and large 15-inch screens for the automotive industry. Key automotive industry features include image enhancements in the form of color enhancement (CE), local-area auto contrast optimization (LACO), sunlight readability enhancement (SRE), 6-axis hue control, and independent white-point adjustment.

“Local area auto contrast is a very important feature in automotive,” Barber said. “The DDIC can adjust the gamma and locally adjust pixel-by-pixel to create the appearance of a brighter color. In an auto environment, image enhancement is a key safety feature to maximize driver awareness. The DDIC is enabling automotive OEMs and their tier 1 suppliers to customize their screens for increased safety and product differentiation.”

Two DDICs can also be cascaded to support larger displays. “The number of displays in a car is going up dramatically” Barber said. “In addition, free-form displays are being introduced as instrument panels with lots of content. There are also initiatives that are putting embedded displays into rear-view mirrors. All these are factors that make the DDIC particularly attractive to the auto industry.”