Microchip Announces Industry's Largest Family of Inductive Position Sensors Now Includes Solution for ISO 26262-Compliant EV Motor

June 20, 2022

News

Extending the broad line of inductive position sensors into the EV motor control market, Microchip Technology announced the LX34070 IC purpose-built for EV motor control applications.

The LX34070 IC includes differential outputs, fast sample rates, and features that make it functional-safety-ready for ISO 26262 compliance in the Automotive Safety Integrity Level–C (ASIL–C) classification.

“The LX34070 inductive position sensor enables lighter, smaller, more reliable motor control solutions that meet stringent safety requirements, reduce overall system costs, and can operate seamlessly and precisely in the noisy environment of an automobile’s DC motors, high currents and solenoids,” said Fanie Duvenhage, vice president of Microchip’s mixed signal and linear analog business unit. “Designers can use the LX34070 to further streamline EV motor control designs by pairing it with other functional-safety-ready Microchip devices including our 8-bit AVR® and PIC® microcontrollers, our 32-bit microcontrollers, and our dsPIC® digital signal controllers.”

The LX34070 inductive position sensor solution offers numerous advantages compared to magnetic resolvers and Linear Voltage Differential Transducers (LVDTs), at a fraction of the cost. By using PCB traces rather than transformer-based magnetic windings and coil structures, the LX34070 device has negligible size and mass compared to alternatives that weigh as much as a pound. Accuracy is improved since the LX34070 does not depend on magnet strength, and the device improves robustness by actively rejecting stray magnetic fields. These and other features give designers greater flexibility over where they can place the thin, lightweight PCB-based LX34070 solution in their EV motor control designs.

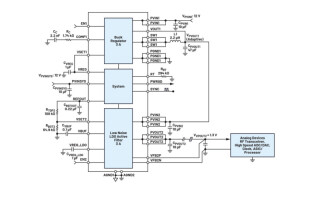

PCB-based inductive position sensors use a primary coil to generate an AC magnetic field that couples with two secondary coils. A small metal target object disturbs the magnetic field so that each secondary coil receives a different voltage whose ratio is used to calculate absolute position. Using these techniques, Microchip introduced its first high-volume inductive sensor for automotive and industrial applications over a decade ago and has many programs in volume production. The LX34070 now brings the same proven PCB materials, approaches and simplified, low-cost packaging to EV motor control and other applications that need its high-speed and low-latency benefits.

Microchip’s LX34070 inductive position sensor IC is available today.

For more infromation visit Microchip’s website.